- Home

- Machinery Directive

- History of the Machinery Directive 2006/42/EC

- Machinery directive 2006/42/EC

- Whereas of machinery directive 2006/42/EC

- Articles of machinery directive 2006/42/EC

- Article 1 of machinery directive 2006/42/EC - Scope

- Article 2 of machinery directive 2006/42/EC - Definitions

- Article 3 : Specific Directives of machinery directive 2006/42/EC

- Article 4 : Market surveillance of machinery directive 2006/42/EC

- Article 5 : Placing on the market and putting into service - machinery directive 2006/42/EC

- Article 6 : Freedom of movement - machinery directive 2006/42/EC

- Article 7 : Presumption of conformity and harmonised standards - machinery directive 2006/42/EC

- Article 8 : Specific measures - machinery directive 2006/42/EC

- Article 9 : Specific measures to deal with potentially hazardous machinery - machinery directive 2006/42/EC

- Article 10 : Procedure for disputing a harmonised standard - machinery directive 2006/42/EC

- Article 11 : Safeguard clause - machinery directive 2006/42/EC

- Article 12 : Procedures for assessing the conformity of machinery - machinery directive 2006/42/EC

- Article 13 : Procedure for partly completed machinery - 2006/42/EC

- Article 14 : Notified bodies - machinery directive 2006/42/EC

- Article 15 : Installation and use of machinery - machinery directive 2006/42/EC

- Article 16 : CE marking - machinery directive 2006/42/EC

- Article 17 : Non-conformity of marking - machinery directive 2006/42/EC

- Article 18 : Confidentiality - machinery directive 2006/42/EC

- Article 19 : Cooperation between Member States - machinery directive 2006/42/EC

- Article 20 : Legal remedies - machinery directive 2006/42/EC

- Article 21 : Dissemination of information - machinery directive 2006/42/EC

- Article 22 : Committee - machinery directive 2006/42/EC

- Article 23 : Penalties - machinery directive 2006/42/EC

- Article 24 : Amendment of Directive 95/16/EC - machinery directive 2006/42/EC

- Article 25 : Repeal - machinery directive 2006/42/EC

- Article 26 : Transposition - machinery directive 2006/42/EC

- Article 27 : Derogation - machinery directive 2006/42/EC

- Article 28 : Entry into force - machinery directive 2006/42/EC

- Article 29 : Addressees - machinery directive 2006/42/EC

- ANNEX I of machinery directive 2006/42/EC - Summary

- GENERAL PRINCIPLES of annex 1 of machinery directive 2006/42/EC

- 1 ESSENTIAL HEALTH AND SAFETY REQUIREMENTS of annex 1 - definitions - machinery directive 2006/42/EC

- Article 1.1.2. Principles of safety integration of annex 1 machinery directive 2006/42/EC

- Article 1.1.3. Materials and products annex 1 machinery directive 2006/42/EC

- Article 1.1.4. Lighting - annex 1 machinery directive 2006/42/EC

- Article 1.1.5. Design of machinery to facilitate its handling - annex 1 machinery directive 2006/42/EC

- Article 1.1.6. Ergonomics - annex 1 machinery directive 2006/42/EC

- Article 1.1.7. Operating positions - annex 1 machinery directive 2006/42/EC

- Article 1.1.8. Seating - annex 1 machinery directive 2006/42/EC

- Article 1.2.1. Safety and reliability of control systems - annex 1 of machinery directive 2006/42/EC

- Article 1.2.2. Control devices - annex 1 of machinery directive 2006/42/EC

- Article 1.2.3. Starting - annex 1 of machinery directive 2006/42/EC

- Article 1.2.4. Stopping - annex 1 of machinery directive 2006/42/EC

- Article 1.2.4.4. Assembly of machinery - Annex 1 of machinery directive 2006/42/EC

- Article 1.2.5. Selection of control or operating modes - annex 1 of machinery directive 2006/42/EC

- Article 1.2.6. Failure of the power supply - annex 1 of machinery directive 2006/42/EC

- Article 1.3. PROTECTION AGAINST MECHANICAL HAZARDS - annex 1 of machinery directive 2006/42/EC

- Article 1.4. REQUIRED CHARACTERISTICS OF GUARDS AND PROTECTIVE DEVICES - annex 1 of machinery directive 2006/42/EC

- Article 1.5. RISKS DUE TO OTHER HAZARDS - annex 1 of machinery directive 2006/42/EC

- Article 1.6. MAINTENANCE - annex 1 of machinery directive 2006/42/EC

- Article 1.7. INFORMATION - annex 1 of machinery directive 2006/42/EC

- Article 2. SUPPLEMENTARY ESSENTIAL HEALTH AND SAFETY REQUIREMENTS - annex 1 machinery directive 2006/42/EC

- Article 3. SUPPLEMENTARY ESSENTIAL HEALTH TO THE MOBILITY OF MACHINERY - annex 1 machinery directive 2006/42/EC

- Article 4. SUPPLEMENTARY REQUIREMENTS TO OFFSET HAZARDS DUE TO LIFTING OPERATIONS of machinery directive 2006/42/EC

- Article 5. SUPPLEMENTARY ESSENTIAL HEALTH AND SAFETY REQUIREMENTS FOR UNDERGROUND WORK of machinery directive 2006/42/EC

- Article 6. SUPPLEMENTARY REQUIREMENTS - HAZARDS DUE TO THE LIFTING OF PERSONS of machinery directive 2006/42/EC

- Annex II : Declarations of CONFORMITY OF THE MACHINERY, DECLARATION OF INCORPORATION - machinery directive 2006/42/EC

- Annex III of machinery directive 2006/42/EC - CE marking

- Annex IV of machinery directive 2006/42/EC

- Annex V of machinery directive 2006/42/EC

- Annex VI of machinery directive 2006/42/EC

- Annex VII - Technical file for machinery - machinery directive 2006/42/EC

- Annex VIII - Assessment of conformity of machinery directive 2006/42/EC

- Annex IX of machinery directive 2006/42/EC - EC type-examination

- Annex X of machinery directive 2006/42/EC - Full quality assurance

- Annex XI of machinery directive 2006/42/EC - Minimum criteria for the notification of bodies

- Annex XII of machinery directive 2006/42/EC - Correlation table between machinery directive 2006/42/CE and MD 1998/37/CE

- Machinery directive 1998/37/EC

- considerings of machinery directive 1998/37/CE

- articles of 1998/37/EC machinery directive

- Annex I of 1998/37/CE machinery directive

- Annex II of 1998/37/EC machinery directive

- Annex III of machinery directive 1998/37/CE

- Annex IV of machine directive 1998/37/EC

- Annex V of machines directive 1998/37/CE

- Annex VI of machines directive 1998/37/EC

- Annex VII of machines directive 1998/37/EC

- Annex VIII of 1998/37/CE machine directive

- Annex IX of machinery directive 1998/37/CE

- Machinery directive 1989/392/EC

- whereas of machinery directive machines 1989/392/EEC

- articles of machinery directive 1989/392/EEC

- Annex I of machinery directive 1989/392/EEC

- Annex II of machine directive 1989/392/EEC

- Annex III of machinery directive 1989/392/EEC

- Annex IV of machinery directive 1989/392/EEC

- Annex V of machinery directive 1989/392/EEC

- Annex VI of machine directive 1989/392/EEC

- Annexe VII of machinery directive 1989/392/EEC

- Amendments of 1989/392/EEC directive

- ATEX directives

- ATEX 94/9/EC directive

- Whereas of ATEX 94/9/CE directive

- Articles of ATEX 94/9/CE directive

- article 1 ATEX 94/9/EC directive

- article 2 ATEX 94/9/EC directive

- article 3 ATEX 94/9/EC directive

- article 4 : ATEX 94/9/EC directive

- article 5 : ATEX 94/9/EC directive

- article 6 : ATEX 94/9/EC directive

- article 7 : ATEX 94/9/EC directive

- article 8 ATEX 94/9/EC directive

- article 9 : ATEX 94/9/EC directive

- article 10 : ATEX 94/9/EC directive

- article 11 : ATEX 94/9/EC directive

- article 12 : ATEX 94/9/EC directive

- article 13 : ATEX 94/9/EC directive

- article 14 : ATEX 94/9/EC directive

- article 15 : ATEX 94/9/EC directive

- article 16 : ATEX 94/9/EC directive

- ANNEX I of ATEX 94/9/EC directive : CRITERIA DETERMINING THE CLASSIFICATION OF EQUIPMENT-GROUPS INTO CATEGORIES

- ANNEX II of ATEX 94/9/EC : directive ESSENTIAL HEALTH AND SAFETY REQUIREMENTS -EHSR

- ANNEX III of ATEX 94/9/EC directive : MODULE EC-TYPE EXAMINATION

- ANNEX IV of ATEX 94/9/EC directive : MODULE PRODUCTION QUALITY ASSURANCE

- ANNEX V of ATEX 94/9/EC directive : MODULE PRODUCT VERIFICATION

- ANNEX VI of ATEX 94/9/EC directive : MODULE CONFORMITY TO TYPE

- ANNEX VII of ATEX 94/9/EC directive : MODULE PRODUCT QUALITY ASSURANCE

- ANNEX VIII of ATEX 94/9/EC directive : MODULE INTERNAL CONTROL OF PRODUCTION

- ANNEX IX of ATEX 94/9/EC directive : MODULE UNIT VERIFICATION

- ANNEX X of ATEX 94/9/EC directive : CE Marking - Content of the EC declaration of conformity

- ANNEX XI of ATEX 94/9/EC directive: NOTIFICATION OF BODIES

- ATEX 99/92/EC Directive

- ATEX DIRECTIVE 2014/34/UE

- whereas of 2014/34/UE ATEX directive

- Articles of ATEX 2014/34/UE directive

- Annex 1 of ATEX 2014/34/UE directive

- Annex 2 of the ATEX 2014/34/UE directive

- Annex 3 of ATEX 2014/34/UE directive

- Annex 4 of ATEX 2014/34/UE directive

- Annex 5 of ATEX 2014/34/UE directive

- Annex 6 of ATEX 2014/34/UE directive

- Annex 7 of ATEX 94/9/EC directive

- Annex 8 of the ATEX 2014/34/UE directive

- Annex 9 of the ATEX 2014/34/UE directive

- Annex 10 of ATEX 2014/34/UE directive

- Annex 11 of ATEX 2014/34/UE directive

- Annex 12 of the ATEX 2014/34/UE directive

- Audits in Ex field - EN 13980, OD 005 and EN ISO/CEI 80079-34

- New ATEX directive

- RASE european project

- ATEX 94/9/EC directive

- IECEX

- Standardization & European Regulation

- Safety of machines : Standardization and European regulations

- European regulation for machines - standardization for machines - harmonized standards

- Standardization in machinery

- EN ISO 12100 - Décembre 2010

- EN ISO 12100-1 - January 2004

- EN ISO 12100-1:2003/A1

- EN ISO 12100-2 November 2003

- EN ISO 12100-2:2003/A1

- EN ISO 14121-1 September 2007

- ISO/TR 14121-2 - 2007

- EN 50205:2002 standard - Relays with forcibly guided (mechanically linked) contacts

- ISO 11161:2007

- ISO 13849-1:2006

- ISO 13849-2:2012

- ISO 13850:2006 - Safety of machinery -- Emergency stop -- Principles for design

- ISO 13851:2002 - Safety of machinery -- Two-hand control devices -- Functional aspects and design principles

- ISO 13854:1996 Safety of machinery - Minimum gaps to avoid crushing of parts of the human body

- ISO 13855:2010 - Safety of machinery -- Positioning of safeguards with respect to the approach speeds of parts of the human body

- ISO 13856-1:2013 Safety of machinery -- Pressure-sensitive protective devices -- Part 1: General principles

- ISO 13856-2:2013 - Safety of machinery -- Pressure-sensitive protective devices -- Part 2: General principles for design testing

- ISO 13856-3:2013 Safety of machinery -- Pressure-sensitive protective devices - Part 3: General principles for design

- ISO 13857:2008 Safety of machinery -- Safety distances to prevent hazard zones

- ISO 14118:2000 - Safety of machinery -- Prevention of unexpected start-up

- ISO 14119:2013- Interlocking devices associated with guards

- ISO 14120:2002 - Guards -- General requirements for the design and construction

- ISO 14122-1:2001 - Permanent means of access to machinery

- ISO 14122-2:2001 - Permanent means of access to machinery

- ISO 14122-4:2004 - Permanent means of access to machinery

- ISO 14123-1:1998 - Reduction of risks to health from hazardous substances emitted by machinery

- ISO 14123-2:1998 - Reduction of risks to health from hazardous substances emitted by machinery

- ISO 14159:2002 - Hygiene requirements for the design of machinery

- ISO 19353:2005 -- Fire prevention and protection

- ISO/AWI 17305 - Safety of machinery - Safety functions of control systems

- ISO/DTR 22100-2 - Safety of machinery -- Part 2: How ISO 12100 relates to ISO 13849-1

- ISO/TR 14121-2:2012 - Risk assessment - Part 2: Practical guidance

- ISO/TR 18569:2004 - Guidelines for the understanding and use of safety of machinery standards

- ISO/TR 23849:2010 - Guidance on the application of ISO 13849-1 and IEC 62061 in the design of safety-related control systems

- STABILITY DATES FOR Machinery STANDARDS

- harmonized standards list - machinery-directive 2006/42/CE

- Publication of harmonised standards for machinery directive 2006/42/EC - 9.3.2018

- Harmonized standard list - machinery directive 2006/42/EC - 9.6.2017

- Harmonized standards for machinery - OJ C 2016/C173/01 of 15/05/2016

- Harmonized standards for machinery -OJ C 2016/C14/102 of 15/01/2016

- Harmonized standards for machinery - corrigendum OJ C 2015/C 087/03 of 13/03/2015

- harmonized standards for machinery - OJ C 2015/C 054/01 of 13/02/2015

- Application guide for machinery directive 2006/42/EC

- Guide to application of the machinery directive 2006/42/CE - July 2017

- Guide to application of the Machinery Directive 2006/42/EC - second edition June 2010

- Guide to application of machinery directive - 1-2 : The citations

- Guide to application of machinery directive - § 3 to § 31 The Recitals

- Guide to application of machinery directive - § 32 to § 156 - The Articles

- Guide to application of machinery directive - § 157 to § 381 - Annex I

- Guide to application of machinery directive - § 382 to § 386 - ANNEX II Declarations

- Guide to application of machinery directive - § 387 - ANNEX III CE marking

- recommendation for use - machinery directive 2006/42/EC

- Notified bodies under the machinery directive 2006/42/CE

- Safety of Ex, ATEX and IECEx equipments : Standardization

- Standardization in Ex Field

- The transposition of the ATEX 94/9/EC Directive to the 2014/34/EU directive

- harmonized standards list - ATEX directive 2014/34/EU

- Harmonized standard list for ATEX 2014/34/UE - 12-10-2018

- Harmonized standard list for ATEX 2014/34/UE - 15.6.2018

- Harmonized standard list for ATEX 2014/34/UE - 12-07-2019

- Harmonized standard list for ATEX 2014/34/UE - 9.6.2017

- Harmonized standards list ATEX 2014/34/UE directive - OJ C 126 - 08/04/2016

- Guide to application of the ATEX Directive 2014/34/EU

- application guide of 2014/34/EU directive - preambule, citations and recitals

- Guide to application of the ATEX 2014/34/UE directive - THE ARTICLES OF THE ATEX DIRECTIVE

- Guide to application of the ATEX 2014/34/UE directive - ANNEX I CLASSIFICATION INTO CATEGORIES

- Guide to application of the ATEX 2014/34/UE directive - ANNEX II ESSENTIAL HEALTH AND SAFETY REQUIREMENTS

- Guide to application of the ATEX 2014/34/UE directive - ANNEX III MODULE B: EU-TYPE EXAMINATION

- Guide to application of the ATEX 2014/34/UE directive - ANNEX IV MODULE D: CONFORMITY TO TYPE

- Guide to application of machinery directive - § 388 - ANNEX IV machinery and mandatory certification

- Guide to application of the ATEX 2014/34/UE directive - ANNEX V MODULE F: CONFORMITY TO TYPE

- Alignment of ten technical harmonisation directives - Decision No 768/2008/EC

- ATEX 94/9/EC directive documents

- ATEX 94/9/EC guidelines

- ATEX 94/9/EC guidelines 4th edition

- 1 INTRODUCTION of ATEX 94/9/EC guidelines 4th edition

- 2 OBJECTIVE OF THE ATEX DIRECTIVE 94/9/EC - ATEX 94/9/EC guidelines 4th edition

- 3 GENERAL CONCEPTS of ATEX 94/9/EC directive ATEX 94/9/EC guidelines 4th edition

- 4 IN WHICH CASES DOES DIRECTIVE 94/9/EC APPLY - ATEX 94/9/EC guidelines 4th edition

- 5 EQUIPMENT NOT IN THE SCOPE OF DIRECTIVE 94/9/EC - ATEX 94/9/EC guidelines 4th edition

- 6 APPLICATION OF DIRECTIVE 94/9/EC ALONGSIDE OTHERS THAT MAY APPLY - ATEX 94/9/EC guidelines 4th edition

- 7 USED, REPAIRED OR MODIFIED PRODUCTS AND SPARE PARTS - ATEX 94/9/EC guidelines 4th edition

- 8 CONFORMITY ASSESSMENT PROCEDURES - ATEX 94/9/EC guidelines 4th edition

- 9 NOTIFIED BODIES - ATEX 94/9/EC guidelines 4th edition

- 10 DOCUMENTS OF CONFORMITY - ATEX 94/9/EC guidelines 4th edition

- 11 MARKING - CE marking -ATEX 94/9/EC guidelines 4th edition

- 12 SAFEGUARD CLAUSE AND PROCEDURE - ATEX 94/9/EC guidelines 4th edition

- 13 EUROPEAN HARMONISED STANDARDS - ATEX 94/9/EC guidelines 4th edition

- 14 USEFUL WEBSITES - ATEX 94/9/EC guidelines 4th edition

- ANNEX I: SPECIFIC MARKING OF EXPLOSION PROTECTION - ATEX 94/9/EC guidelines 4th edition

- ANNEX II: BORDERLINE LIST - ATEX PRODUCTS - ATEX 94/9/EC guidelines 4th edition

- ATEX 94/9/EC guidelines 4th edition

- Harmonized standards list - ATEX 94/9/EC directive

- Harmonized standards list ATEX 94/9/EC directive - OJ C 126 - 08/04/2016

- Harmonized standards list ATEX 94/9/EC - OJ C 335 - 09/10/2015

- Harmonized standards list ATEX 94/9/EC - OJ-C 445-02 - 12/12/2014

- Harmonized standards list ATEX 94/9/EC - OJ-C 076-14/03/2014

- Harmonized standards list ATEX 94/9/EC - OJ-C 319 05/11/2013

- ATEX 94/9/EC guidelines

- European regulation for ATEX 94/9/EC ATEX directive

- Guide to application of ATEX 2014/34/EU directive second edition

- Safety of machines : Standardization and European regulations

- Latest news & Newsletters

- Functional safety

- Terms and definitions for functional safety

- Safety devices in ATEX

- The SAFEC project

- main report of the SAFEC project

- Appendix 1 of the SAFEC project - guidelines for functional safety

- Appendix 2 of the SAFEC project

- ANNEX A - SAFEC project - DERIVATION OF TARGET FAILURE MEASURES

- ANNEX B - SAFEC project - ASSESSMENT OF CURRENT CONTROL SYSTEM STANDARDS

- ANNEX C - safec project - IDENTIFICATION OF “USED SAFETY DEVICES”

- Annex D - SAFEC project - study of ‘ Used Safety Devices’

- Annex E - Determination of a methodology for testing, validation and certification

- EN 50495 standard for safety devices

- The SAFEC project

- Safety components in Machinery

- STSARCES - Standards for Safety Related Complex Electronic Systems

- STSARCES project - final report

- STSARCES - Annex 1 : Software engineering tasks - Case tools

- STSARCES - Annex 2 : tools for Software - fault avoidance

- STSARCES - Annex 3 : Guide to evaluating software quality and safety requirements

- STSARCES - Annex 4 : Guide for the construction of software tests

- STSARCES - Annex 5 : Common mode faults in safety systems

- STSARCES - Annex 6 : Quantitative Analysis of Complex Electronic Systems using Fault Tree Analysis and Markov Modelling

- STSARCES - Annex 7 : Methods for fault detection

- STSARCES - Annex 8 : Safety Validation of Complex Components - Validation by Analysis

- STSARCES - Annex 9 : safety Validation of complex component

- STSARCES - Annex 10 : Safety Validation of Complex Components - Validation Tests

- STSARCES - Annex 11 : Applicability of IEC 61508 - EN 954

- STSARCES - Annex 12 : Task 2 : Machine Validation Exercise

- STSARCES - Annex 13 : Task 3 : Design Process Analysis

- STSARCES - Annex 14 : ASIC development and validation in safety components

- Functional safety in machinery - EN 13849-1 - Safety-related parts of control systems

- STSARCES - Standards for Safety Related Complex Electronic Systems

- History of standards for functional safety in machinery

- Basic safety principles - Well-tried safety principles - well tried components

- Functional safety - detection error codes - CRC and Hamming codes

- Functional safety - error codes detection - parity and chechsum

- Functional safety and safety fieldbus

- ISO 13849-1 and SISTEMA

- Prevention of unexpected start-up and machinery directive

- Self tests for micro-controllers

- Validation by analysis of complex safety systems

- basic safety principles - safety relays for machinery

- Download center

- New machinery regulation

- Revision of machinery directive 2006/42/EC

- security for machines

10 DOCUMENTS OF CONFORMITY - ATEX 94/9/EC guidelines 4th edition

10 DOCUMENTS OF CONFORMITY

10.1 Documents issued by the manufacturer

10.1.1 EC Declaration of Conformity51

Once the manufacturer has undertaken the appropriate procedures to assure conformity with essential requirements of the Directive it is the responsibility of the manufacturer or his authorised representative established in the EU to affix the CE marking and to draw up a written EC Declaration of Conformity.

The manufacturer or his authorised representative established within the EU keeps a copy of this EC Declaration of Conformity for a period of ten years after the last equipment has been manufactured.

Where neither the manufacturer nor his authorised representative is established within the EU, the obligation to keep the copy of the EC Declaration of Conformity available is the responsibility of the person who places the product on the EU market.

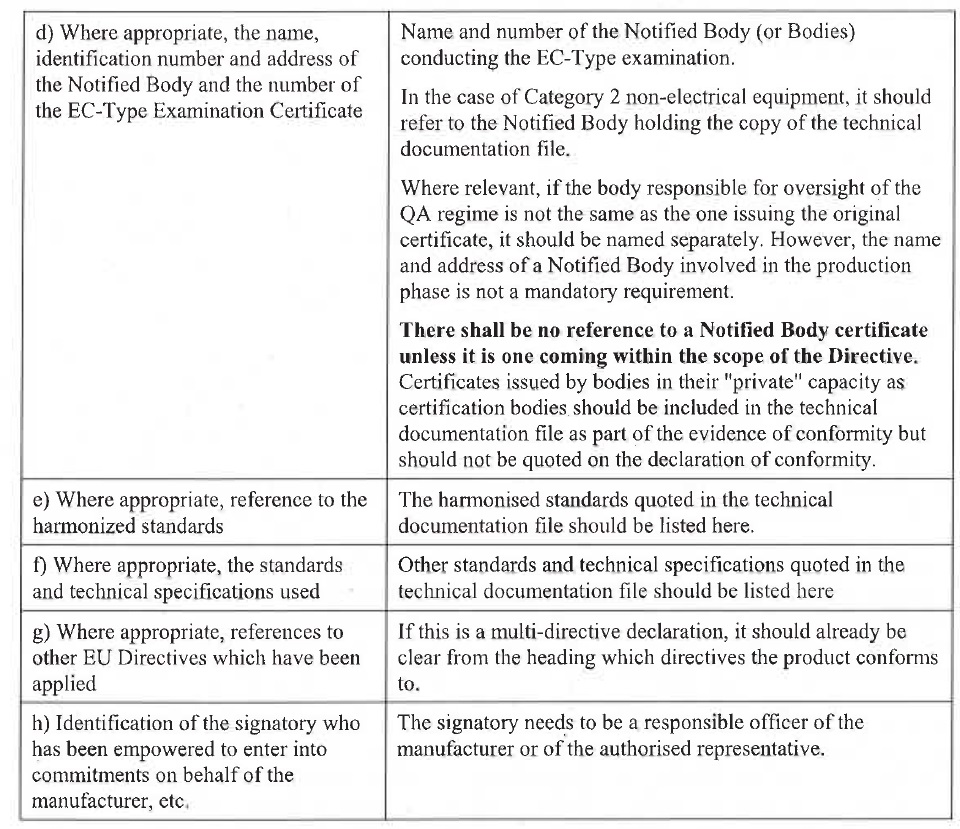

In respect of the Notified Bodies possibly involved in the conformity assessment procedure the EC Declaration of Conformity must contain, where appropriate, the name, identification number and address of the Notified Body and the number of the EC-Type Examination Certificate. The name and address of a Notified Body involved in the production phase, where relevant, is not a mandatory requirement.

As far as assemblies of ATEX equipment are concerned, if an assembly is to be treated as a new item of ATEX equipment the EC Declaration of Conformity needs only to identify the unit and the related information. Details of the items of equipment making up the assembly will be included on the technical file. However, there is a duty on all those in the supply chain to pass on the relevant information relating to the items of equipment where these have been previously placed on the market accompanied by their own EC Declaration of Conformity and instructions.

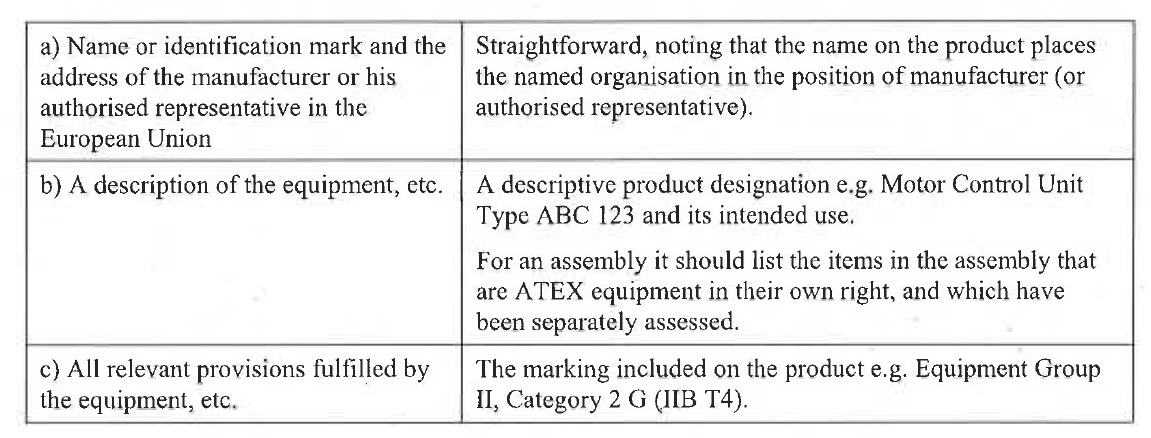

Annex X.B of the Directive states what the EC Declaration of Conformity must contain. Further information can be found in section 5.4 of the "Blue Guide". As a general rule, the content of the EC Declaration of Conformity contains the following:

10.1.2 Written Attestation of Conformity for components

The EC Declaration of Conformity should not be confused with the written Attestation of Conformity for components mentioned in Article 8(3) of Directive 94/9/EC. In addition to declaring the conformity of the components with the provisions of the Directive, the written attestation of conformity has to state the characteristics of the components and how the components are to be incorporated into equipment or protective systems to ensure that the finished equipment or protective system meets the applicable Essential Health and Safety Requirements of Directive 94/9/EC.

10.1.3 Documents accompanying the product

According to Articles 4(2) and 5(1) of Directive 94/9/EC and for the purposes of market surveillance the EC Declaration of Conformity / the written Attestation of Conformity must accompany the information given with each single product, or each batch of identical products delivered for the same end user.

The product is also accompanied by instructions for safe use (see EHSR 1.0.6 of Annex II to the ATEX Directive 94/9/EC). The manufacturer shall provide to the user written instructions that include the necessary information for repair, maintenance and/or overhaul of the equipment concerned. The manufacturer does not have to provide the full technical file.

EHSR 1.0.6 does not specify the form of the instructions. It is generally agreed that all health and safety related instructions must be supplied in paper form, since it cannot be assumed that the user has access to the means of reading instructions supplied in electronic form or made available on an Internet site. However, it is often useful for the instructions to be made available in electronic form and on the Internet as well as in paper form, since this enables the user to download the electronic file if he so wishes and to recover the instructions if the paper copy has been lost. This practice also facilitates the updating of the instructions when this is necessary.

The user takes into account the instructions issued by the manufacturer to carry out repair, maintenance and/or overhaul on the basis of the requirements of the applicable directives (as 2009/104/EC - Use of work equipment by workers at work and 1999/92/EC - Protection of workers potentially at risk from explosive atmospheres) and of relevant specific national legislation that regulates the repair, maintenance and overhaul of used equipment. The instructions must contain drawings and diagrams necessary for repair of the equipment. Applicable and technically accepted standards can also be used, for example EN 60079-19 - Explosive atmospheres - Equipment repair, overhaul and reclamation.

However, where necessary, the manufacturer can include in his documentation a statement that specific repair, maintenance and/or overhaul of the equipment shall only be conducted by the manufacturer himself, or by a repairer he has qualified or authorized.

With respect to assemblies, it is important to the safe installation, operation and maintenance of the assembled unit that all relevant information is passed to the end user. The manufacturer of the assembled unit should do this by including all related information in a package supplied to the end user.

10.1.4 Retention of documentation - Quality assurance

According to Annex IV, paragraph 5 of the ATEX Directive 94/9/EC the manufacturer, or where relevant, the authorised representative or importer) shall, for a period ending at least 10 years after the last piece of equipment was manufactured, be able to make available to the national authorities:

- the documentation of the quality system;

- updating of the quality system;

- • audit reports and certificates of the Notified Body. Larger organisations have a certified quality management system according to the ISO 9000 standards. For these manufacturers it is recognised that it is difficult to keep all quality documents and all changes to the quality system for such a long period. It is the opinion of the ATEX Standing Committee that the requirements in Annex IV, paragraph 5 of the ATEX Directive 94/9/EC are fulfilled if the manufacturer keeps at the disposal of the national authorities at least the actual quality management system documents + the following documents which have to be kept for a period ending at least 10 years after the last piece of equipment was manufactured:

- audit reports and certificates of the ISO 9000 certifier. This will be one or two audit reports per year that include the actual state at that moment of the quality system with changes;

- audit reports and notifications of the Notified Body that issued the Production Quality Assurance Notification.

The above consideration is against the background that this documentation shall always be sufficient so as to enable surveillance authorities to determine that the relevant conformity assessment procedure(s) was/were applied in a satisfactory manner and that the relevant obligations of the ATEX Directive 94/9/EC were fulfilled.

10.1.5 Acceptance of test results of manufacturers by a Notified Body

Test reports can be a part of the technical documentation the manufacturer has to present to the Notified Body and the latter may take them into consideration appropriately.

Concerning safety relevant aspects in connection with Annex III (EC-Type examination) and Annexes V (Product verification) and IX (Unit verification) to Directive 94/9/EC, a Notified Body's independent and transparent intervention vis-à-vis the client and all interested parties (e.g. Member States, European Commission, manufacturers, Notified Bodies) is required legally. Therefore a Notified Body only may accept test reports of manufacturers under certain conditions. The requirements included in the standard EN ISO/IEC 17025 General requirements for the competence of testing and calibration laboratories (ISO/IEC 17025) shall be used as basis for acceptance of test results.

The Notified Body has to state the acceptance of test results in his test report.

In any case the Notified Body remains fully responsible for accepted test results and for the EC-Type Examination Certificate (Annex III) or Certificate of Conformity (Annexes V and IX) based on them.

10.2 Documents issued by the Notified Body

The Notified Body issues the following documents according to the provisions of the relevant conformity assessment procedures:

- EC-Type Examination Certificate;

- product and production quality assurance notification;

- conformity to type notification;

- product verification, certificate of conformity;

- unit verification, certificate of conformity.

These documents need not accompany the product.

It is not possible to issue an EC-Type Examination Certificate for products of Category 2 nonelectrical equipment and of Category 3, as mentioned in Article 8(1)(b)(ii) and 8(1)(c). Further, it is also not permissible to list such goods on an EC-Type Examination Certificate issued for goods of categories other than these. This is because an EC-Type Examination Certificate is an attestation that the goods listed on it have undergone the necessary conformity assessment procedures that result in the issuing of an EC-Type Examination Certificate; it is not necessary for such goods to undergo such conformity assessment procedures.

Where a single item is covered by more than one category, it may be permissible to issue an EC-Type Examination Certificate. Under such circumstances, these items need to comply with the highest applicable conformity assessment requirements (see section 8.1). If this requirement results in an EC-Type Examination Certificate being issued, these goods are permitted to be listed on an EC-Type Examination Certificate.

A typical example of this is found in the semiconductor fabrication industry where a high vacuum pump is used to extract hydrogen but cannot meet the physical clearances necessary to justify Category 2. Category 3 is adequate for the process as the pump is normally filled with pure hydrogen at low pressure, so there is no ignition risk except during the very brief transitions between operation and non-operation.

In this case, it is only the electrical part that is truly subject to EC-Type examination but it is already established that a mechanical part can be considered along with the electrical part if they are integral with each other, rather than a mere assembly.

In such cases, it is not unreasonable to mention such items in the same set of documentation i.e. the goods have an EC-Type Examination Certificate issued for them.

However, where the goods are discrete items e.g. two different type categories of a hand-held radio, one of which is Category 2 and the other Category 3, a single EC-Type Examination Certificate should never be issued; the Category 3 goods should be listed on a separate document that in no way implied it was an EC-Type Examination Certificate. The same should be true for components of items.

However, the voluntary issue of a certificate for goods that are not permitted to be listed on an EC-Type Examination Certificate is possible. The certification body may not give an indication on the certificate that it is a Notified Body because it would not be acting in that capacity. Therefore, the number of the Notified Body must not be affixed. Further, it is not permissible to affix the CE marking to such certificates. There is no objection for the hexagon (Ex mark) to be used or to make reference to Directive 94/9/EC.

Provision of evaluation and test results with EC-Type Examination Certificates: although being a separate document, the report describing how the equipment fulfils the Essential Health and Safety Requirements of the Directive is considered to be integral to the provision of a certificate. Evaluation and test results supporting the decision to issue an EC-Type Examination Certificate should accompany the certificate from the Notified Body to the manufacturer.

10.2.1 Minimum content of a European standardised ATEX Test and Assessment Report

The term "test report" is used in a twofold way. In fact certification in scope of 94/9/EC is based on three levels of reports:

- test in a laboratory, for example the measurement of a temperature, following called test report;

- assessment to the requirements of harmonised standards, following called assessment report;

- assessment to the Essential Health and Safety Requirements of the Directive, following called assessment report, too.

Having very different types of test reports issued, varying from very poor reports, hardly including any information, to test reports with detailed test and evaluation results, a standardised ATEX Assessment Report format enables and ensures the following goals:

- Recognizable as an ATEX Assessment Report.

- Specified minimum content.

- Meeting the requirements for test reports as laid down in EN ISO/IEC 17025 and other applicable standards.

- Easy to use/integrate with existing formats currently used by all ATEX Notified Bodies.

- An ATEX Assessment Report is only issued if all applicable requirements are met and if all tests have been conducted with positive results (but still allowing waiving tests provided that the reasoning is given in the test report).

Recognizable as ATEX Assessment Report

The ATEX Assessment Report should be easy to identify as such by manufacturers, Ex Notified/Certification Bodies and any other party as a genuine ATEX Assessment Report. To realise this, an identical approach could be followed as for the content and format of ATEX Annex III EC-Type Examination Certificates; laid down in ExNB Clarification Sheet No. ExNB/09/340. Another possibility is to just require the use of the wording "ATEX Assessment Report" (exact wording to be agreed upon) on the cover page of the report; without the need for a standardized template for the ATEX Assessment Report as has been done for Annex III Certificates.

Specified minimum content

The report shall contain a minimum amount of information that enables manufacturers to easily obtain other local/regional approvals/certificates based on the information in the report and any associated test documentation. An assessment report issued by an ATEX Notified Body that supports the issue of an EC Type Examination shall contain:

- General information about the product, type designation, applicant, manufacturer, types of protection, technical data.

- Technical evaluation of the construction of the equipment. For most types of protection this can be a checklist (Yes/No/Not applicable + remarks) combined with the test documentation

that specifies the construction; for intrinsic safety however a descriptive format is usually the best (if not the only) useable format. A detailed assessment narrative that confirms compliance with the standards used to support compliance with the ATEX Directive. If no standards are used, then the assessment narrative shall confirm compliance with the Directive. Since explosion safety standards are concept standards occasionally some interpretation is involved: the report should make clear how the assessment has been carried out.

• Results of tests

- o details of tests carried out, relevant information about the test conditions, method and results shall be provided as part of the test report;

- o details of tests that have been waived and the justification for waiving those tests (the standard EN 60079-0 calls for a justification for waiving tests) shall be part of the assessment report;

- o details of tests that have been accepted from other organisations, test laboratories, etc. and a justification for accepting those tests shall be part of the assessment report. If tests are being accepted from other sources, then this should be clear, because the body that produces that data should be scrutinised. It could easily be disguised that test data from unsuitable sources had been used.

• Routine tests, if any: applicable to the product and agreed upon between the manufacturer and the Notified Body (applicable standards are EN 13980 or IEC 80079-34, too).

Requirements for reporting

An ATEX Test Report shall meet all requirements for the content of test reports as

- specified in EN ISO/IEC 17025. In practice, this should not be any problem for a Notified Body since all conduct and report testing according to EN ISO/IEC 17025;

- an ATEX Assessment Report shall meet all requirements as specified in EN 45011.

Easy to use and integrate by Notified Bodies

It should be easy to integrate the European standardized ATEX Assessment Report in the operational procedures and documents used by a Notified Body. This requires that the format itself should not be 100% specified in detail, but only to the extent that all parties involved – issuing and receiving Notified Bodies and manufacturers – know what to find in the test report. So the focus is on the content of the report, not its layout, numbering, etc. This should make it easy to implement the ATEX Assessment Report in the existing way of working of all individual Notified Bodies. It should not cause a significant increase (if any) in the costs for the manufacturer to obtain an ATEX Certificate.

Full report

To avoid any confusion about the expected content of an ATEX Assessment Report, such report should only be issued when the product involved meets all applicable requirements and has passed all applicable tests with positive results. An ATEX Assessment Report shall not be issued in case of any negative results or in case that only a part of the applicable requirements (for example IP54 requirements) have been evaluated or tested. This does not preclude the issuance of an ATEX Assessment Report for an Ex component, certified under a "U" certificate.

If a report with negative results or not fully assessed applicable requirements is given to the manufacturer is must be unambiguous that this is not an ATEX Assessment Report.

10.3 EC-Type Examination Certificate and the responsibilities of stakeholders

A Type Examination Certificate attests that a specimen (including instructions, as appropriate) representative of the production envisaged by the manufacturer fulfils the relevant applicable provisions of the Directive, in particular the Essential Health and Safety Requirements (EHSRs).

The question arises as to the actions that need to be taken when the "generally acknowledged state of the art" has developed. It is clear that the original specifications applied may continue to show fulfilment of the EHSRs and the Type Examination Certificate then remains valid.

However, over time the "generally acknowledged state of the art" can develop substantively such that the specifications originally applied no longer ensure the type examined complies with the EHSRs. It should be noted that the question of whether there has been substantive development of the state of the art is not left to discretionary interpretation by the Notified Body, but has equally to be generally acknowledged by the technical community of the stakeholders. The publication of a revised harmonised standard would be one way to recognise a development in the state of the art: in this case, the responsible European Standardisation Organisation (ESO) shall determine whether the state of the art concerning the EHSRs has changed, and if so, in what respects. The ESO shall indicate this in the foreword of each standard.

In such cases, if the specifications and evaluation criteria originally applied to a product no longer ensure that it complies with the latest state of the art, the Type Examination Certificate is no longer valid and further action is required. Given reasonable transition periods and knowledge of current developments, it is expected that the manufacturer will have sufficient time to contact a Notified Body to undertake the necessary re-evaluation so that there is a smooth transition from one set of applied specifications to another. Notified Bodies, who are expected to maintain a good knowledge of developments in the state of the art, should make arrangements to alert the holders of their EC-Type Examination Certificates to the revision of harmonised standards.

It should be noted, however, that the issuing of a new Type Examination Certificate will have no retroactive effect and, therefore, will not affect products placed on the market and/or put into service whilst the manufacturer was in possession, where appropriate, of a valid Certificate.

It should also be re-affirmed that the overall responsibility for compliance of the product rests with the manufacturer who, where required, must ensure that a valid Certificate is in his possession, as well as that all relevant conformity documents correspond to the current state of the art. In parallel, the Notified Body must provide all the relevant information for the manufacturer in order to ensure that the existing Certificate is correct in its evaluation that the type continues to meet the EHSRs.

English